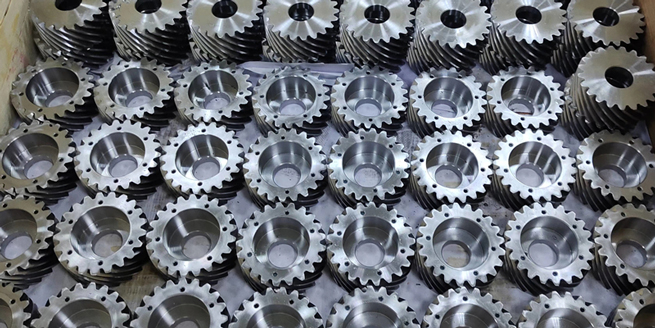

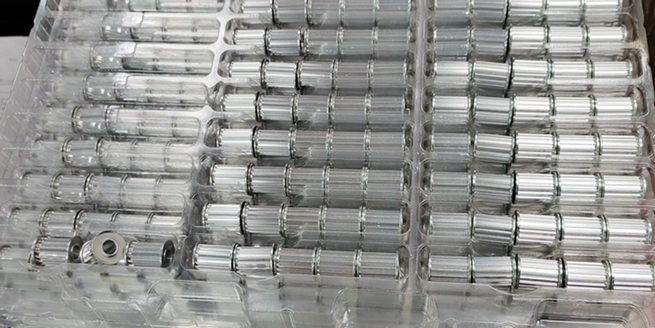

refers to the large-scale production of components using Computer Numerical Control (CNC) machining processes. This approach involves the utilization of automated machines guided by computer programs to manufacture a high quantity of identical parts with precision and efficiency. High volume production is characterized by the continuous and rapid manufacturing of components, often in large batches, to meet the demands of mass production. This method is employed across various industries, including automotive, aerospace, and electronics, where consistent, high-quality parts are required in significant quantities to satisfy market demands and achieve cost-effectiveness through economies of scale.

Utilize advanced CAM (Computer-Aided Manufacturing) software to optimize toolpaths, reducing cycle times and enhancing efficiency in producing large quantities of parts.

Efficient Programming:

Optimize toolpaths using advanced CAM software for faster production and reduced cycle times.

Multi-Axis Machining:

Utilize multi-axis CNC machines to simultaneously cut complex parts in one setup, accelerating production.

Automation Integration:

Implement robotic systems for loading/unloading to enhance efficiency and maintain continuous operation.

Rigorous Quality Control:

Employ automated inspection tools for consistent quality throughout high-volume production maching.

Scalable Production Planning:

Create flexible plans to adapt to demand fluctuations, utilizing real-time monitoring for efficient production.

Cost Efficiency: Achieve economies of scale, reducing per-unit production costs as volume increases.

Consistent Quality: CNC complex machining ensures precision and consistency across a large number of parts, maintaining high-quality standards.

Speed and Efficiency: Automation and optimized processes in high volume machining lead to faster production cycles and increased efficiency.

Reduced Lead Times: Streamlined workflows and efficient machining processes contribute to shorter lead times for large production runs.

Scalability: CNC machining is highly scalable, allowing for seamless adaptation to varying production demands.

Specialized Expertise: Outsource when specialized expertise is required for specific machining processes or materials.

Capacity Constraints: When in-house capacity is limited, outsourcing ensures timely production without compromising quality.

Cost-Effective Solutions: Outsourcing to facilities with optimized processes can often result in cost savings for high-volume production.

Quick Turnaround: When rapid turnaround is crucial, outsourcing to facilities with available capacity expedites production.

Falcon MFG stands at the forefront of supply chain flexibility through advanced CNC machining for production. With agile production planning, they swiftly adapt to changing market demands, providing scalable solutions that seamlessly adjust to fluctuating production needs. The efficiency of CNC technology allows for just-in-time manufacturing, reducing inventory overhead. Falcon's expertise in handling diverse materials and offering customization at scale ensures tailored solutions without compromising efficiency. The centralized high-volume machining streamlines logistics, consolidating efforts for an agile and responsive supply chain. Falcon MFG's commitment to machining excellence establishes them as a trusted partner for dynamic and reliable production.