Automotive machining refers to the process of manufacturing precision components and parts for automobiles using various machining techniques. These components are integral to the functionality, safety, and performance of vehicles. Automotive machining involves shaping, cutting, and finishing raw materials, typically metals or alloys, to create components that meet the rigorous standards and specifications set by the automotive industry. The precision and quality of these machined parts are crucial for the proper functioning of vehicles. Common auto precision machining processes include milling, turning, drilling, and grinding, and the components produced can range from engine parts to suspension components and transmission parts. The goal is to produce durable, high-performance, and reliable machining automotive parts that contribute to the overall efficiency and safety of vehicles.

These 5 machining processes collectively contribute to the production of a wide range of automotive components, ensuring precision, efficiency, and the ability to meet the rigorous standards of the automotive industry.Here are in below:

Milling and Turning:

Description: Milling involves rotary cutters to shape components, while turning rotates a workpiece on a lathe to achieve cylindrical shapes.

Applications: Used for creating engine components, chassis parts, and other automotive parts with diverse geometries.

5-Axis Machining:

Description: Utilizes a CNC machine with five axes for simultaneous cutting, allowing complex shapes to be produced in a single setup.

Applications: Ideal for intricate components where access from multiple angles is necessary, enhancing efficiency and precision.

Swiss Machining:

Description: Specialized machining method using a Swiss-type lathe for high-precision turning of small, intricate parts.

Applications: Suited for small, complex automotive components like screws, bolts, and other precision parts.

Electrical Discharge Machining (EDM):

Description: Uses electrical discharges to erode material, especially effective for machining hardened materials.

Applications: Applied in automotive manufacturing for shaping molds, dies, and intricate components like gears.

Grinding:

Description: Abrasive machining process to achieve tight tolerances, improve surface finish, and remove material.

Applications: Commonly used for precision grinding of automotive components such as camshafts, crankshafts, and bearings.

1. Prototyping Precision: CNC machining facilitates accurate prototyping for automotive parts machining, allowing for quick design evaluation and adjustments.

2. Design Optimization: Designs can be refined based on prototype results by utilizing custom automotive machining, ensuring optimal part geometries and manufacturing methods.

3. Efficient Tooling and Molds: CNC machining is integral to the creation of precise tooling and molds, enhancing the efficiency and reliability of the manufacturing process.

4. Versatile Material Application: With the ability to work with diverse materials, CNC machining accommodates the varied material requirements in automotive manufacturing, from metals to plastics.

5. Seamless Scalability: From small-batch production to large-scale manufacturing, CNC machining provides a scalable solution with consistent precision, contributing to time-to-market efficiency.

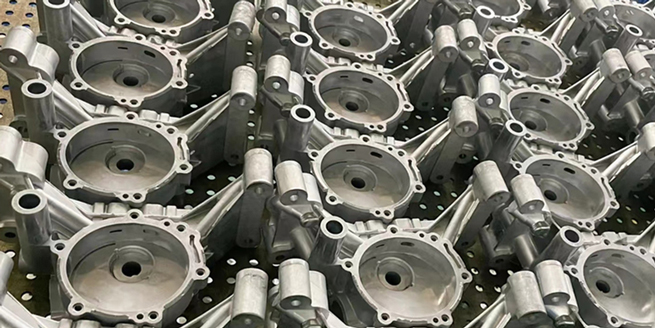

CNC machining is widely used in the automotive industry for producing various precision components. Here are some types of automotive parts machining that are commonly CNC machined:

Engine Components:

Cylinder heads

Pistons

Transmission Parts:

Gears

Shafts

Suspension Components:

Control arms

Steering knuckles

Brake System Parts:

Brake calipers

Brake rotors

Exhaust System Components:

Exhaust manifolds

Exhaust pipes

Chassis Components:

Frame brackets

Crossmembers

Interior Components:

Dashboard components

Seat brackets

Exterior Components:

Grilles

Mirrors

Electrical Components:

Sensor brackets

Electrical connectors

Custom Components:

Specialty or custom-designed parts for unique vehicle models or aftermarket modifications.

Falcon MFG excels in high-volume automotive parts production through cutting-edge CNC machining technology. Their precision machining ensures consistent accuracy, facilitating seamless transitions from efficient prototyping to scalable mass production. The versatility in handling various materials and complex geometries, coupled with advanced tooling and mold creation, underscores Falcon's commitment to quality. Automated inspection processes guarantee stringent quality standards, contributing to the reliability and safety of automotive components. Falcon's cost-effective solutions, driven by CNC precision, make them a trusted partner in the automotive industry for achieving excellence in high-volume manufacturing.