5-axis machining refers to the ability of a machine tool to move a part or a tool on five different axes simultaneously. These axes are typically labeled as X, Y, Z, A, and B. In a traditional 3-axis machining center, the tool can move along the X, Y, and Z axes, while in 5-axis machining, the tool can also tilt and rotate about the A and B axes. This additional movement allows for much more complex and intricate machining operations.

The basic working principle involves moving the cutting tool across the workpiece in five different directions, providing greater flexibility and precision in manufacturing complex geometries.

The "5" in 5-axis machining refers to the number of directions in which the cutting tool can move. These directions are typically defined as X, Y, Z, A, and B axes, allowing for five degrees of freedom in motion.

X, Y, Z Axes: Linear movements along these axes.

A Axis: Rotation around the X-axis.

B Axis: Rotation around the Y-axis.

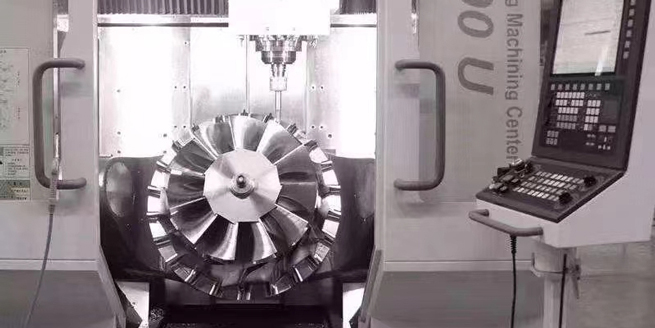

CNC (Computer Numerical Control) is used in 5-axis machining for precise control over the machine tool movements. CNC controllers interpret the design specifications and convert them into specific movements and actions for the machine. This level of automation and precision is crucial for achieving complex shapes and geometries in 5-axis machining.

Complex Geometries: 5-axis machining allows for the production of highly intricate and complex parts that would be challenging or impossible to produce with traditional machining methods.

Reduced Setups: With 5-axis machining, multiple faces of a part can be machined in a single setup, reducing the need for multiple setups and improving overall efficiency.

Higher Precision: The ability to approach a part from multiple angles ensures higher precision in machining, as the tool can reach difficult-to-access areas.

Reduced Tool Changes: 5-axis machining can often complete a part with fewer tool changes, reducing production time and improving tool life.

5-axis machining is particularly useful for producing complex parts with intricate shapes and contours. Industries that benefit from 5-axis machining include aerospace (for turbine blades and complex components), automotive (for molds and prototypes), medical (for implants and custom medical devices), and general precision machining for various applications.

3+2 Axis Machining: In this approach, the machine tool is capable of 5-axis movements, but the additional axes (A and B) are used only to position the workpiece at a specific angle. The actual cutting is done in 3 axes, similar to a traditional 3-axis machine. This method reduces the need for multiple setups.

5 Axis Machining: This involves simultaneous cutting with all five axes, offering more flexibility and precision. It allows for continuous toolpath motion, enabling the machining of complex parts without reorienting the workpiece.

In summary, while 3+2 axis machining is more about positioning, 5-axis machining involves simultaneous cutting, providing greater capabilities for complex part production. The choice depends on the specific requirements of the part and the efficiency needed in the manufacturing process.

Choosing the right 5-axis machining company, such as Falcon MFG, is crucial for the success of your project. Here are some considerations to help you make an informed decision:

Experience and Expertise: Prioritize companies with a proven track record and expertise in 5-axis machining.

Capabilities and Equipment: Assess the company's machining capabilities, ensuring they use modern and well-maintained equipment.

Quality Assurance: Verify the presence of robust quality control processes to ensure precision and reliability.

Materials and Industries: Choose a company with experience in handling the specific materials and industries relevant to your project.

Communication and Collaboration: Select a company that communicates effectively, collaborates with clients, and offers excellent customer support.

To begin 5-axis machining with Falcon CNC complex precision Machining, initiate contact through their website or directly. Share comprehensive project details, including design specifications and materials. Request a detailed quote, considering costs and turnaround time. Provide design files for clarity, ensuring Falcon CNC has the capabilities and equipment for your project. Confirm terms, including payment and delivery schedules. Discuss quality assurance processes and approve prototypes if applicable. Maintain regular communication for progress updates and address concerns promptly. Conduct a final inspection upon completion and coordinate the delivery or pickup of the finished, precision-machined parts. Open collaboration ensures a successful 5-axis machining experience with Falcon CNC Machining.