Create by Falcon MFG Engineering Team 2025/03/20

1. Introduction

The demand for complex machining is surging as industries like aerospace, medical, and automotive push the boundaries of innovation. Complex parts—defined by intricate geometries, multi-material compositions, and micron-level tolerances—require advanced manufacturing solutions. Traditional 3-axis CNC machines struggle with:

Geometric complexity: Undercuts, thin walls, and freeform surfaces (e.g., turbine blades with 0.2 mm wall thickness).

Material limitations: Machining titanium alloys and carbon fiber composites without delamination.

Cost inefficiency: Multiple setups increasing scrap rates by up to 15%.

5-axis CNC machining addresses these challenges by enabling simultaneous multi-angle toolpaths, reducing cycle times by 40% and achieving ±0.005 mm tolerances. For example, SpaceX uses 5-axis CNC to produce rocket engine nozzles with internal cooling channels, a feat impossible with conventional methods.

Explore Our 5-Axis Machining Capabilities

2. Core Technologies: 5-Axis Machining & AI-Driven Programming

2.1 5-Axis CNC Machining

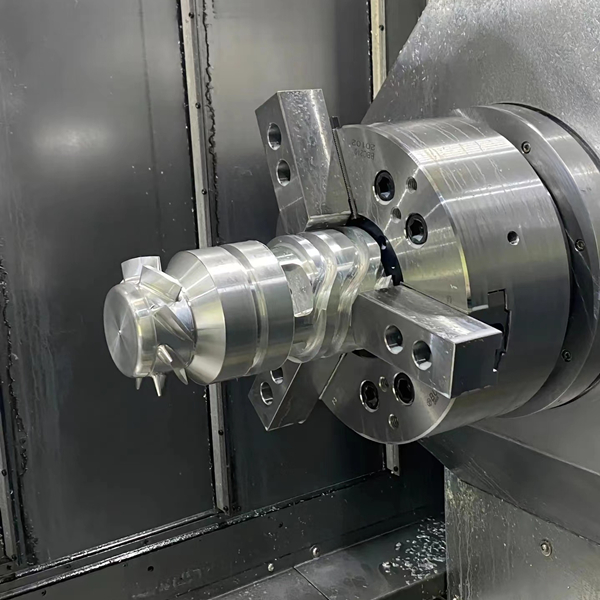

5-axis machines rotate tools and workpieces along five axes, eliminating repositioning errors. Applications include:

Medical: Titanium parts, requiring Ra 0.4µm surface finishes.

Medical: Hip implants with porous structures for bone integration.

Case Study:

A Formula 1 team reduced brake caliper production time from 12 hours to 6 hours using 5-axis machining, achieving ±0.003 mm accuracy on 7075-T6 aluminum.

2.2 AI-Driven CAM Software

Siemens NX CAM and Mastercam’s Adaptive Clearing optimize toolpaths for complex parts:

Adaptive Milling: Reduces tool wear by 30% and cycle times by 25%.

Collision Avoidance: Real-time simulations prevent $50k+ machine damage.

3. Material Innovation: Lightweighting & Extreme Environments

3.1 Titanium Alloys (Ti-6Al-4V)

Applications: Aircraft landing gear, spinal implants.

Benefits: 45% lighter than steel, withstands 800°C temperatures.

3.2 Carbon Fiber Reinforced Polymers (CFRP)

Challenges: Delamination during drilling.

Solution: Diamond-coated tools and dry machining achieve ±0.01 mm accuracy.

3.3 Inconel 718

Applications: Turbine blades, nuclear reactors.

Machining Strategy: High-pressure coolant (1,000+ psi) prevents work hardening.

4. Industry Applications: Aerospace, Automotive & Medical

4.1 Aerospace: Turbine Blades & Fuel Nozzles

Material: Inconel 718

Tolerances: ±0.005 mm for aerodynamic efficiency.

Case: engine nozzles, reducing fuel burn by 15%.

4.2 Automotive: EV Battery Trays

Material: 6061-T6 aluminum

Design: Single-piece construction with integrated cooling channels.

Weight Reduction: 30% vs. steel, extending EV range by 20%.

4.3 Medical: Orthopedic Implants

Material: Ti-6Al-4V ELI (ASTM F136)

Surface Finish: Ra 0.1µm for biocompatibility.

Need Precision Complex Parts? ISO 9001 Certified | 7-Day Prototyping. Request a Free Quote →

5. Future Trends: Smart Factories & Sustainability

5.1 Digital Twins

Digital replicas of CNC machines predict tool wear and optimize feeds/speeds in real time. For example, Rolls-Royce uses digital twins to extend turbine blade tool life by 25%.

5.2 Sustainable Machining

Minimum Quantity Lubrication (MQL): Reduces coolant usage by 90%.

Recycled Materials: 70% post-industrial scrap in aluminum billet sourcing.

6. Quality Assurance: Certifications & Testing

6.1 Certifications

IATF 16949: Automotive zero-defect production.

ISO 13485: Medical component traceability.

6.2 Inspection Technologies

CMM: 100% dimensional checks for complex geometries.

CT Scanning: Detects internal voids as small as 10µm in medical implants.

7. Why Partner with Falcon CNC?

7.1 Technical Capabilities

50+ 5-Axis Machines: DMG Mori NHX 6300, Mazak Integrex i-200.

Swiss CNC Lathes: Micro-machining down to Ø0.5 mm.

7.2 Global Support

Rapid Prototyping: 5-day turnaround for urgent orders.

Bulk Discounts: 15% cost reduction on 1,000+ units.

Transform Your Complex Part Production Today! 24/7 Support | Global Delivery. Contact Our Experts →

8. Case Study: High-Pressure Pump Housing for Offshore Oil Rigs

Client: Global Energy Supplier

Challenge: Premature failure of stainless steel housings in corrosive seawater.

Solution:

Material Switch: Duplex stainless steel (UNS S32205) with PREN > 40.

5-Axis Machining: Single-setup production of 500 housings/month.

Surface Treatment: Electropolishing to Ra 0.2µm.

Results:

50% Longer Lifespan: Passed 1,500-hour ASTM G48 testing.

20% Cost Savings: Reduced scrap from 12% to 2%.

9. Material Innovations on the Horizon

9.1 Metal Matrix Composites (MMCs)

Applications: Brake rotors, satellite components.

Benefits: 60% lighter than steel with 2x thermal conductivity.

9.2 Ceramic-Coated Alloys

Applications: Hypersonic vehicle components.

Performance: Withstand 1,200°C for 500+ cycles.