Falcon High Volume Machining stands as a pinnacle in large-scale production, crafting 10,000,000 precision components monthly. With a robust arsenal of 300+ cutting-edge machines and 1000+ CNC machining materials. Committed to quality, Falcon High Volume Machining, holds ISO 9001, 16949, and 13485 certifications, ensuring the highest standards and machining service in high-volume manufacturing. Falcon's unparalleled capabilities deliver efficiency, precision, and diversity, making us the trusted choice for industries requiring massive production capacities without compromising on quality.

The Advantages of Falcon High Volume Machining Service

Efficiency and Scale

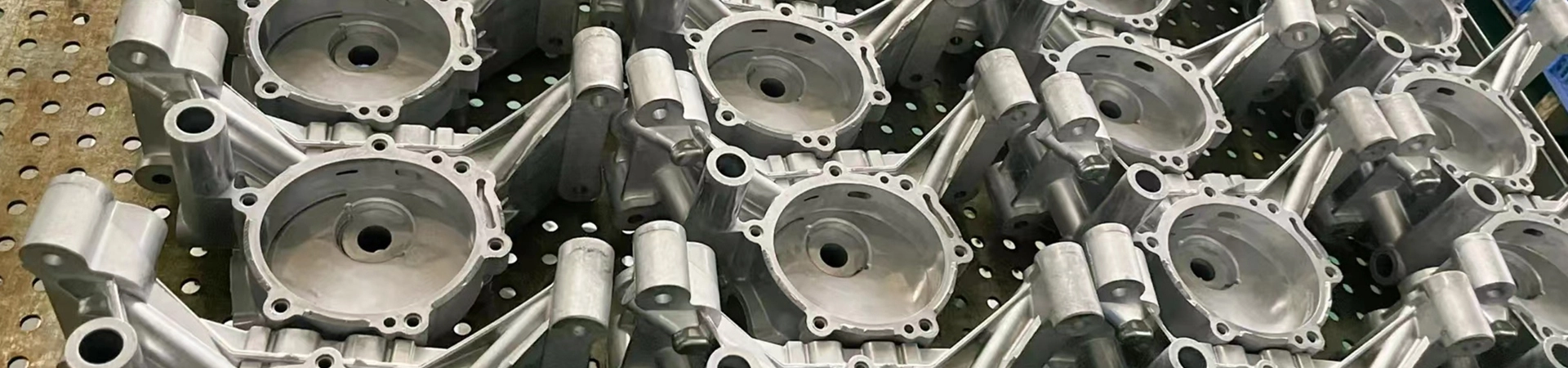

Falcon High Volume Machiningdelivers large-scale production with advanced 5-axis CNC technology, achieving tolerances as tight as ±0.005mm for industries like automotive high volume CNC machining components (e.g., EV battery housings, transmission parts) and electronics high volume machining for circuit boards. Our 300+ machines and automated workflows reduce lead times by 40%, supporting 50,000+ unit/month orders with 72-hour turnaround for JIT supply chains.

Diverse Capabilities

Material Expertise: With 1,000+ CNC machining materials, including 6061-T6 aluminum for robotics high volume machining custom automation parts and PEEK for medical high volume precision machining parts, we cater to complex geometries and stringent industry demands.

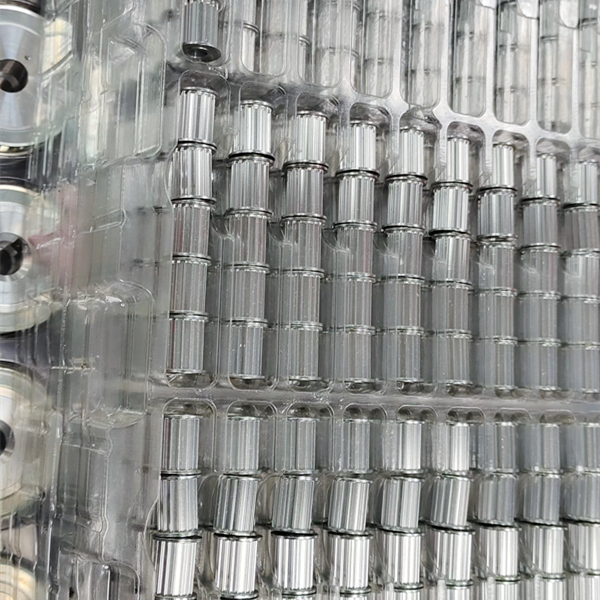

Technology Integration: 28+ CNC technologies and 21+ surface finishes ensure solutions for communications high volume machining connector housings (e.g., EMI-shielded 5G enclosures) and medical implant-grade components. Swiss machining handles micron-level precision for intricate robotics gears.

Quality Assurance

Backed by ISO 9001, 16949, and 13485 certifications, Falcon guarantees zero-defect production for critical applications:

Automotive: ADC12 die-cast EV components with <0.1mm dimensional variance.

Medical: FDA-compliant surgical tools via cleanroom machining and CMM inspection.

Communications: Anodized aluminum 5G antenna housings.

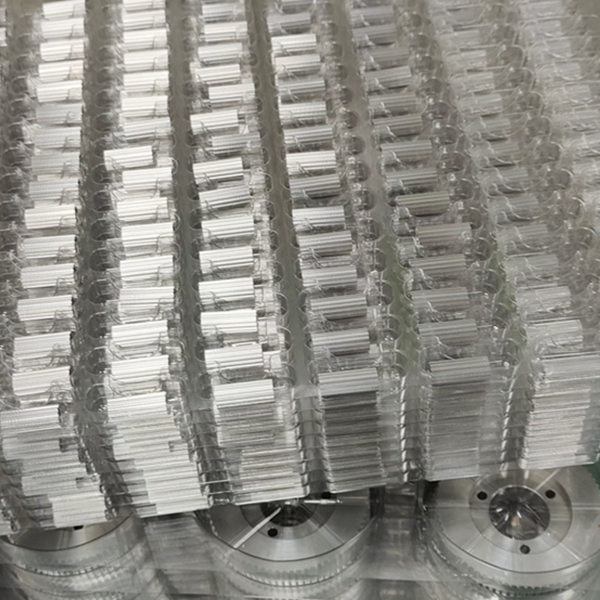

High Volume CNC Machining:

Falcon excels in large-scale CNC machining, ensuring precision and efficiency in the production of high quantities of components with advanced technology and expertise.

Swiss Machining Service:

Our Swiss machining capabilities deliver intricate details with precision, making it ideal for components requiring complex geometries in high-volume machining production runs.

Specializing in die casting, Falcon provides cost-effective solutions for intricate and lightweight parts, maintaining high-quality standards in large-scale manufacturing processes.

Call

Address

#41 Jinlei Industrial Zone, Xiaotang Road, Youganpu, Fenggang, Dongguan