Create by Falcon MFG Engineering Team 2025/03/30

Aluminum die casting is a cornerstone of modern manufacturing, enabling the production of lightweight, durable, and complex metal parts. From automotive components to consumer electronics, this process has revolutionized how industries meet their design and performance demands. In this guide, we’ll dive into the fundamentals of aluminum die casting, its applications, materials, and how Falcon CNC Machining stands out as your trusted partner for high-quality solutions.

What Is Aluminum Die Casting?

Aluminum die casting is a metal-forming process where molten aluminum is injected under high pressure into a steel mold (or "die") to create precise, dimensionally stable parts. This method is ideal for high-volume production due to its speed, repeatability, and ability to produce intricate geometries with tight tolerances. Compared to other casting methods, aluminum die casting offers superior strength-to-weight ratios and excellent thermal conductivity, making it a favorite in industries like automotive, electronics, and industrial machinery.

The Aluminum Die Casting Process

The process involves four key stages:

Mold Design: Custom dies are machined from hardened steel to match the part’s specifications. Advanced CAD/CAM software ensures precision, especially for complex shapes.

Melting and Injection: Aluminum alloys are melted at ~660°C and injected into the die under pressures up to 1,500 bar.

Cooling and Ejection: The molten metal solidifies within seconds, and the part is ejected automatically.

Post-Processing: Trimming, machining, and surface treatments (e.g., anodizing, powder coating) enhance functionality and aesthetics.

For high-volume projects, automated systems like robotic arms and real-time quality monitoring ensure consistency.

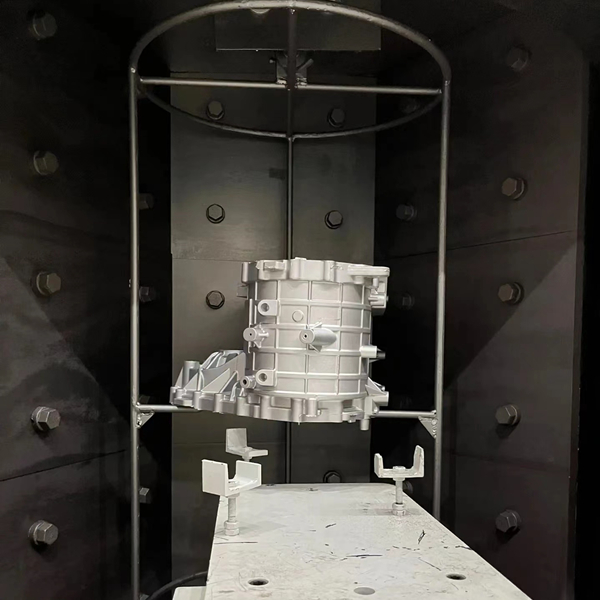

Typical Die-Casted Aluminum Components

Aluminum die casting excels in producing:

Engine housings (e.g., transmission cases, cylinder heads)

Heat sinks for electronics

Structural brackets in automotive and construction

Consumer electronics enclosures (e.g., laptops, power tools)

Hydraulic valve bodies for industrial machinery.

These parts benefit from aluminum’s corrosion resistance, thermal stability, and lightweight properties.

Aluminum Alloys for Die Casting

Five common alloys dominate the industry:

A380: Offers excellent fluidity and thermal conductivity, ideal for automotive parts.

A383 (ADC12): Known for high strength and pressure tightness, used in electronics and machinery.

A360: Superior corrosion resistance for marine and outdoor applications.

A413: Excellent pressure tightness, often used in hydraulic systems.

B390: High wear resistance, suited for engine blocks and brake components.

Each alloy is selected based on mechanical requirements, such as tensile strength (150–320 MPa) and elongation (3–10%)3.

Industry Applications (Beyond Aerospace)

Aluminum die casting serves seven key sectors:

Automotive: Engine brackets, transmission housings, and EV battery trays.

Electronics: Heat sinks, smartphone frames, and connector housings.

Construction: Door handles, window fittings, and structural supports.

Industrial Machinery: Pump housings, valve bodies, and conveyor components.

Consumer Goods: Appliance parts, power tool casings, and lighting fixtures.

Medical Devices: MRI machine components and surgical tool handles.

Renewable Energy: Solar panel frames and wind turbine parts.

High-Volume Aluminum Die Casting Capabilities

Mass production demands precision and efficiency. Falcon CNC Machining employs:

Multi-Slide Die Casting Machines for complex geometries.

Vacuum-Assisted Casting to minimize porosity.

In-House Tooling for faster mold adjustments.

Automated Quality Control with 3D scanning and CMMs.

Our facilities produce up to 10,000 tons annually, ensuring scalability for projects of any size. learn more about die casting DirectIndustry Die Casting Guide

7 Expert Tips for Successful Aluminum Die Casting

Optimize Wall Thickness: Uniform walls (2–5 mm) prevent warping and ensure even cooling.

Design Draft Angles: A 1–3° angle eases part ejection and extends mold life.

Avoid Sharp Corners: Radius edges (≥0.8 mm) reduce stress concentrations.

Select the Right Alloy: Match material properties to operational demands (e.g., A380 for high heat).

Incorporate Ribs and Bosses: Enhance strength without adding weight.

Plan for Post-Processing: Specify surface finishes early to avoid redesigns.

Partner with Experienced Manufacturers: Leverage expertise in mold design and process optimization.

5 Factors When Choosing an Aluminum Die Casting Manufacturer

Certifications: ISO 9001, IATF 16949, and RoHS compliance ensure quality. (Learn more about ISO Certification Standards)

In-House Capabilities: Integrated services (mold design, machining, finishing) reduce lead times.

Material Expertise: Knowledge of alloys and their applications prevents costly errors.

Production Volume: Confirm minimum order quantities (MOQs) align with your needs.

Turnaround Time: Automated systems and multiple production lines enable faster delivery.

Why Choose Falcon CNC Machining?

With over 20 years of experience, Falcon CNC Machining combines cutting-edge technology with unparalleled expertise:

Custom Solutions: Tailored die casting services for prototypes and high-volume runs.

Competitive Pricing: In-house tooling and machining reduce overhead costs.

Global Shipping: Reliable logistics to the US, EU, and Asia.

Quality Assurance: Advanced inspection tools, including CMMs and X-ray testing.

Explore our CNC machining services for complementary finishing options.

CTA: Ready to elevate your project? Request a free quote today!

Aluminum Die Casting FAQs

Q1: What are the advantages of aluminum die casting over plastic injection molding?

A: Aluminum offers superior strength, heat resistance, and recyclability, making it ideal for high-stress applications311.

Q2: Can aluminum die casting parts be recycled?

A: Yes! Aluminum is 100% recyclable without losing quality, reducing environmental impact11.

Q3: What surface finishes are available for die-cast parts?

A: Options include anodizing, powder coating, polishing, and chemical film (e.g., Alodine)411.

Q4: How do I reduce costs in aluminum die casting?

A: Simplify designs, use standardized molds, and order larger volumes to amortize tooling costs10.

Q5: What industries do you serve?

A: We support automotive, electronics, medical, and renewable energy sectors, among others.

Ready to Elevate Your aluminum die casting Designs?

�� Email: project@falconcncmachining.com