Al-Mg alloys combine lightweight properties, corrosion resistance, and high strength-to-weight ratios, making them critical for aerospace, automotive, and industrial applications. At Falcon CNC, we utilize 5-axis CNC technology and IATF 16940-certified processes to machine components like aircraft brackets, EV battery trays, and heat exchangers. Our expertise spans alloys such as 5052, 6061, and custom blends with Sc/Zr additions for enhanced performance

Aerospace: CNC-machined Al-Mg-Sc-Mn-Zr brackets reduce aircraft weight by 25% while maintaining tensile strengths up to 320 MPa, validated through ASTM B209 standards45.

Automotive: Al-5052 battery trays with integrated cooling channels improve thermal management by 20%, meeting IATF 16949 compliance for EV applications.

Electronics: Al-Mg-Si (6061) RF shielding plates achieve 98% IACS conductivity, ideal for 5G infrastructure.

Optimize Your Al-Mg Components Today!

Request Material Guide →

Free Technical Consultation | 15% Bulk Discounts

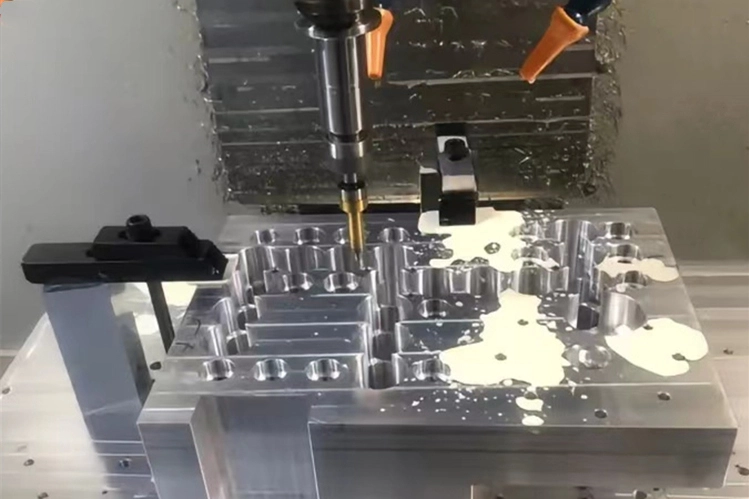

Discover Falcon CNC’s expertise in machining 5052 and 6061 Al-Mg alloys for marine, automotive, and industrial applications. Achieve ±0.005 mm tolerances and Ra 0.8µm finishes.

5052 Al-Mg:

Applications: Marine hardware, fuel tanks, and HVAC systems.

Benefits: Superior saltwater corrosion resistance, 40% lower cost than 6061.

6061-T6:

Applications: Aerospace frames, robotics arms, and structural components.

Benefits: 310 MPa tensile strength, ideal for high-stress environments.

Technical Edge:

Cryogenic Machining: Reduces tool wear by 20% for complex geometries.

Post-Processing: Anodizing or electropolishing enhances durability and aesthetics.

Case Study: High-Performance Al-Mg-Sc-Zr Alloy for Additive Manufacturing

Client: Aerospace Component Manufacturer

Challenge: Poor mechanical properties in L-PBF-printed Al-Mg parts limited lifespan.

Solution:

Material: Al-Mg-Sc-Mn-Zr alloy with 0.2% Zr/0.3% Er additions.

Heat Treatment: Annealing at 300°C for 2 hours to precipitate nano-sized Al3(Sc, Zr) phases.

Results:

30% Higher Tensile Strength: 320 MPa UTS vs. standard Al-Mg.

50% Corrosion Resistance Improvement: Validated via ASTM G48 testing.

Call

Address

#41 Jinlei Industrial Zone, Xiaotang Road, Youganpu, Fenggang, Dongguan