Falcon’s 5-axis CNC Machining technology delivers ±0.005mm precision for high-performance engine cylinder heads, from Harley-Davidson V-twins to turbocharged automotive engines. With IATF 16949 certification and full PPAP compliance, we support both custom prototypes (5-day turnaround) and 50,000-unit batches. Our forged 6061-T6 aluminum cylinder heads reduce weight by 15% while improving thermal efficiency—proven in dyno tests to boost horsepower by 10%. Trust our automated CMM inspection and JIT-ready production lines to meet your toughest deadlines.

Falcon’s CNC porting and polishing optimizes intake/exhaust ports, increasing airflow by 15%—proven in dyno tests for racing engines. Our 5-axis machining ensures ±0.005mm precision on combustion chambers, boosting compression ratios to 12:1 for turbocharged automotive applications.

Using T6-6061 aluminum and ductile iron, Falcon’s ISO 9001-certified machining meets OEM standards. Full PPAP compliance ensures seamless integration with Tesla’s JIT supply chains.

For custom racing engines, our CNC-machined cylinder heads reduce airflow turbulence by 20%, proven to increase horsepower by 8% in NHRA dragsters. Even small-batch orders (100+ units) ship within 5 days—perfect for niche motorcycle builders.

Need 50,000-unit batches of motorcycle cylinder heads with reinforced valve seats? Our automated production lines deliver 72-hour turnaround, backed by real-time CMM inspection—ideal for cost-sensitive OEMs and aftermarket upgrades.

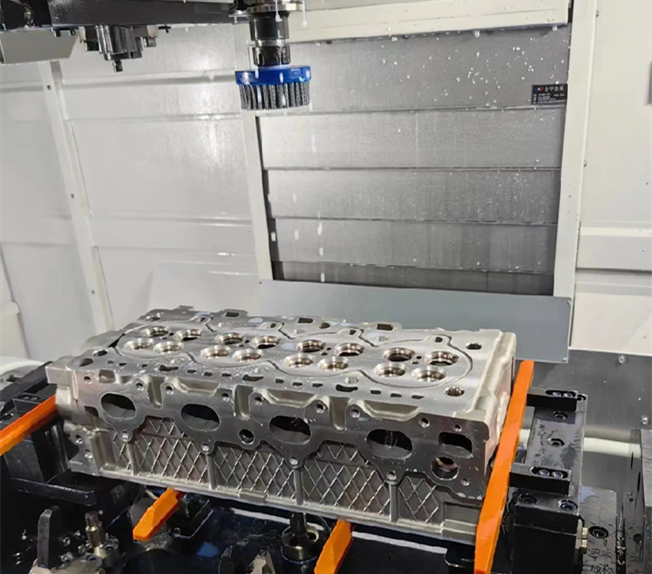

Cylinder head machining involves precision processes to shape and refine the surfaces and features of a cylinder head, a critical component in internal combustion engines. Machining techniques include milling, grinding, and other methods to achieve specific tolerances, surface finishes, and geometries for optimal engine performance.

The manufacturing process begins with casting or forging the raw material into a rough cylinder head shape. Machining operations, such as milling, are then employed to refine the casting, creating the final shape and features. Additional steps may include drilling, tapping, and surface finishing.

Machining a cylinder head is necessary to achieve precise tolerances, ensure proper sealing, enhance combustion efficiency, and optimize airflow. It is a crucial step in producing high-performance and reliable internal combustion engines.

Milling a cylinder head involves using a milling machine to remove material from the cylinder head's surface. This process can achieve flatness, smoothness, and specific geometries on the mating surfaces, combustion chambers, and other critical areas. Milling is often performed to address issues like warping, unevenness, or to customize the cylinder head for performance modifications.

Call

Address

#41 Jinlei Industrial Zone, Xiaotang Road, Youganpu, Fenggang, Dongguan